March 19, 2021

Published by Kranlyft Group

The fixed telehandlers are increasing in popularity

This year started of with Magni Telescopic Handlers extending its fixed frame telehandlers range. The TH range of telescopic handlers for construction and light industry is designed to ensure maximum performance in every situation. Standard 4-wheel drive guarantees maximum grip on any kind of ground. The hydrostatic transmission ensures optimal off-road performance. The compact size is ideal for tight working spaces, guaranteeing maximum manoeuvrability in any location.

• Lowered design for greater stability

• Available with Deutz Stage V engines

• Available in two engine sizes, to suit your needs

• 350 bar L/S hydraulic system

• Four-wheel drive (4WD)

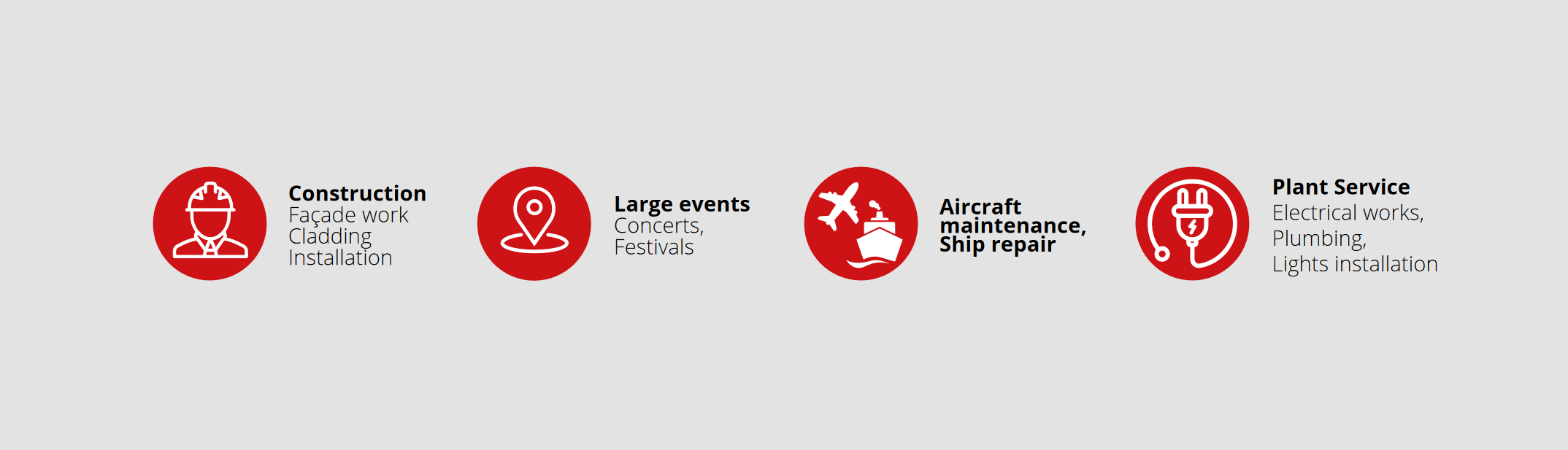

New applications for the fixed telehandlers are emerging and the increase in popularity reflects the markets need for innovative and high-quality telehandlers. Some of the most used applications are as follows:

• Construction

• Large events

• Aircraft maintenance

• Ship repair

• Plant service

The new models have very low stowed booms for a lower centre of gravity, which also provides a slightly unusual look when it is fully elevated. The cab has the same high specification as that fitted to Magni’s fully rotatable telescopic handlers and includes a seven inch intuitive touch screen, cab pressurisation and filtration, air conditioning and a super deluxe seat. Power comes from a Stage V compliant engine of the highest quality. The hydraulic system uses a high pressure pump delivering 350bar/5,100psi, with automatic load sensing and flow control to ensure maximum efficiency and multi function operation. Side shift, automatic eight degrees of levelling and automatic attachment recognition are all standard and includes a winch option for suspended loads.

FUNCTIONALITY

The function management software is easy and intuitive and suitable for all types of users. The thematically organised display and iconographic graphics make it easier to learn the basic functions, making the system user-friendly. The CAN BUS electrical system simplifies the machine management, allowing all relevant data to be displayed on the touchscreen in the cab. The L/S hydraulic system features a 350 bar working pressure. It has been designed to optimize daily work.

COMFORT

Ergonomics and operator comfort are prerogatives of Magni machines. The seat and adjustable steering column are designed to ensure an optimal driving position. The full-visibility cab is designed to guarantee a 360° view during every movement. The many standard features of the cab (such as air filtration and pressurization) ensure operator comfort in any season and location.

ENGINE

All TH models feature Stage V engines to meet the requirements of Regulation (EU) 2016/1628 regarding emissions. All the models are also available with Stage IV final and IIIA engines. This choice was dictated by the desire to be able to easily find the entire range in all markets, without the need for conversion kits. The TH 5.5.19 and TH 5.5.15 models are available with two different motor powers for each available engine. Thus, we can meet the most diverse requirements of each customer, adapting to their needs in the best possible way.

LEVELLING SYSTEM ON TYRES

This mechanism lets the driver adjust the machine levelling and have the full load chart for all operations, even with ground inclinations which would normally affect the lifting performance. Magni has also introduced an additional levelling safety device: if the operator tries to manually correct the inclination of the machine on uneven terrain, the system detects the machine inclination and only allows compensation to be performed in the correct direction, preventing any movement which could worsen the situation.

Watch the introduction video below for a more in-depth feature of the new TH range.

Feel free to contact us for more information.

For more information:

Jurgen Vater, CEO at Kranlyft Group

+46 703 343 053 | jurgen.vater@kranlyft.com

More news

Kranlyft in Sweden to represent Manitex Valla

Valla appointed Kranlyft Group as its authorized distributor for SwedenFrom March 2024 Manitex Valla https://www.valla.com/en/ has appointed Kranlyft Group as its authorized distributor for Sweden. Kranlyft will offer the complete range of industrial self-propelled...

We are moving to new premises

We are moving from Mölnlycke to MölndalWe are delighted to share that Kranlyft Group in Sweden is moving to new premises. As of February 12, 2024, our new address will be Taljegårdsgatan 12, 431 53 Mölndal, Sweden.This move represents an important milestone for...

Glass at dizzying heights

Can we help your company raise the expectations of cranes?In the middle of Sundbyberg, Stockholm Sweden, Edin's Kranar´s operator Tommy Eriksson maneuvers glass partitions at astonishing heights at Swedbank's new headquarters. Up to an impressive 47 meters up and...

Kranlyft UK is now an authorized distributor for Terex® Self-Erecting Cranes in the UK and Ireland.

We are pleased to announce that we are now offering the entire range of Terex Self-Erecting Cranes, which includes the latest CSE series and the exclusive FC 6.24 – Europe’s sole self-erecting top-slewing crane. This offering encompasses sales, service, and parts assistance.

Products & services

Let us introduce you to our complete range of innovative products and our great services.

Contact Us

+44 117 982 6661

+46 31 807 000

Book an Appointment

Are you interested in our product range and wish to experiance any specific models first hand?